Borescopes for Aircraft Maintenance

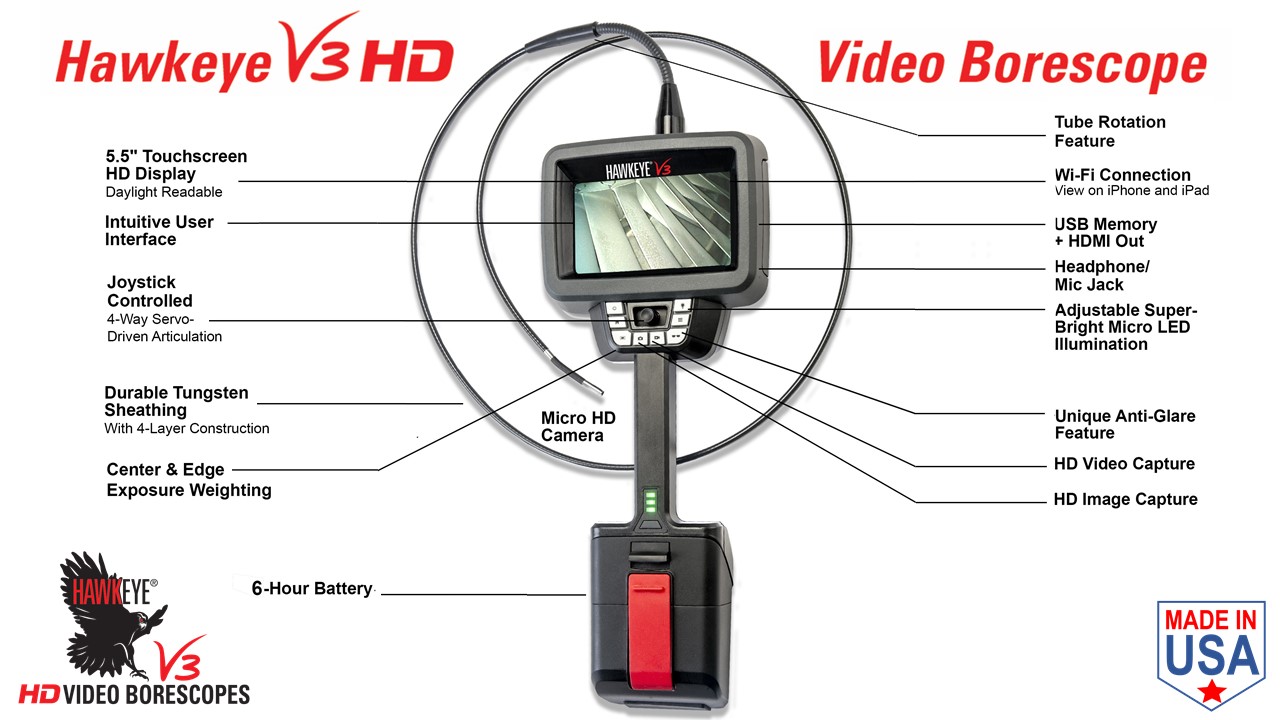

Hawkeye® Video borescopes allow aircraft maintenance technicians to perform inspections in the engine and airframe where it is impossible to see without tearing down the engine. Many of todays aircraft engines are “on-condition” which means they need to be inspected by a video borescope at a certain interval of time to determine if the engine needs maintenance or can continue to fly. The quality of videoscopes is one borescope application that cannot by overlooked, like the new Hawkeye® V3 HD Video Borescope, provide users with crystal clear, bright HD images and videos allowing them to easily identify the condition of an aircraft engine.

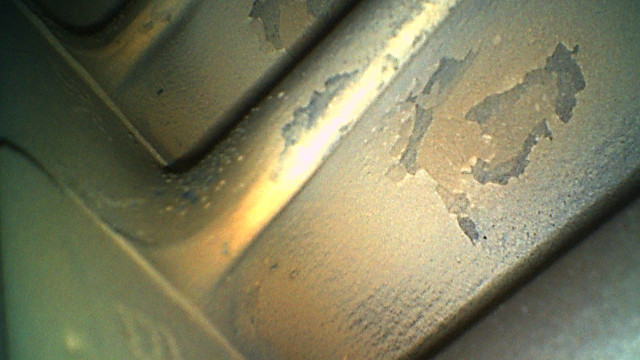

Turbine blades in a P&W PT6A-34 aircraft engine inspected with a Hawkeye® V3 HD Video Borescope.

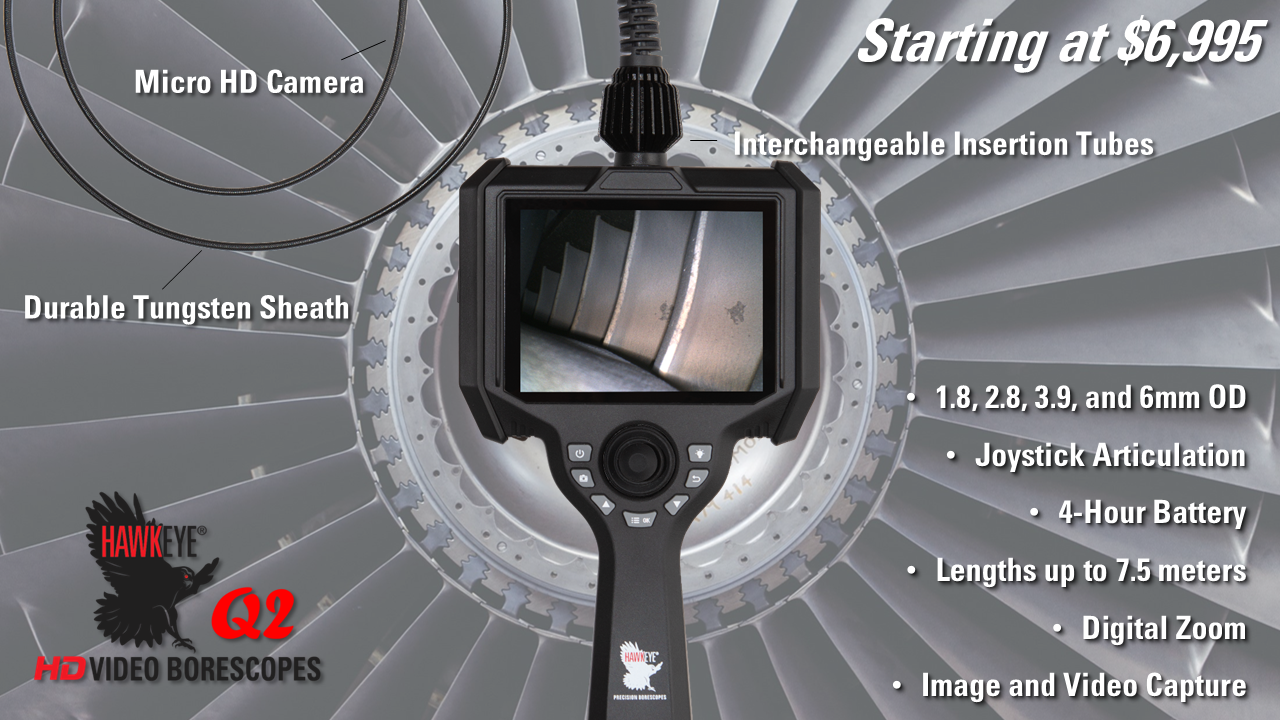

Allison 250 aircraft engine Inspection with a Hawkeye® Q2 HD Video Borescope.

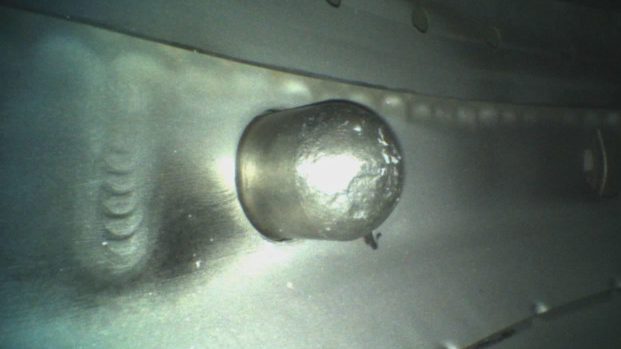

Fuel nozzle in a P&W PT6A-34 aircraft engine inspected with a Hawkeye® V3 HD Video Borescope

Tom Pentecost , VP of Maintenance and Flightline Group Inc. in Tallahassee, FL, and mechanic Stephanie Nita, use the borescope application provided by the Hawkeye® V3 HD Video Borescope with WiFi capability to simultaneously view the image on an iPad while inspecting a PT6A-34 engine.

If you have questions about other aircraft borescope applications, please give us a call at 800-536-0790; we look forward to speaking with you.

Why the Hawkeye V3 HD Video Borescope is the Best Solution for Aviation Maintenance

Aviation maintenance demands precision, reliability, and top-notch quality. The Hawkeye V3 HD Video Borescope is a standout choice for several reasons:

Best Image Quality: The V3 Video borescope’s HD video and advanced optics deliver clear, detailed images, making it easy to spot even the smallest defects. This high-quality imaging is essential for ensuring the safety and performance of aircraft.

Made in the USA: Proudly manufactured in the United States, the Hawkeye V3 meets rigorous quality standards. This ensures that aviation maintenance professionals can trust its performance and durability.

Versatile and Flexible: With features like 4-way servo joystick articulation and adjustable LED lighting, the Hawkeye V3 can adapt to various inspection tasks. Whether it’s a narrow turbine blade or a broader engine cavity, this borescope handles it all with ease.

Robust Durability: Designed to withstand harsh environments, the Hawkeye V3 is both rugged and reliable. Its waterproof design and robust tungsten-braided sheath ensure it can endure routine environment in maintenance hangars.

User-Friendly: The portable and ergonomic design makes it easy to handle, even during lengthy inspections. The intuitive interface reduces training time and operator fatigue, allowing technicians to focus on thorough and efficient inspections.

Outstanding Customer Service: Renowned for exceptional customer support, we ensure that users receive the help they need, enhancing the overall experience with the product.

The Hawkeye V3 HD Video Borescope is an indispensable tool for aviation professionals. By integrating this advanced borescope into their maintenance routines, technicians can ensure higher safety standards, better performance, and more efficient operations.

For more details, visit the Hawkeye V3 HD Video Borescope.