Borescope Origins: Where It All Began

August 20, 2021

Borescope cameras are the industry standard when it comes to the proper examination of heavy machinery. And while the use of this tool is commonplace, the history of how it became one of the world’s most popular examination devices is not as well known.

From the borescope camera’s conception in the early sixties, those in the industry have heralded this device as a revolutionary inspection tool. Further, developers have perfected their designs to keep up with rapid advancements in technology and the complexities of new machinery throughout the years. Read about the fascinating history behind these marvelous inventions in our comprehensive outline of borescope origins and where it all began.

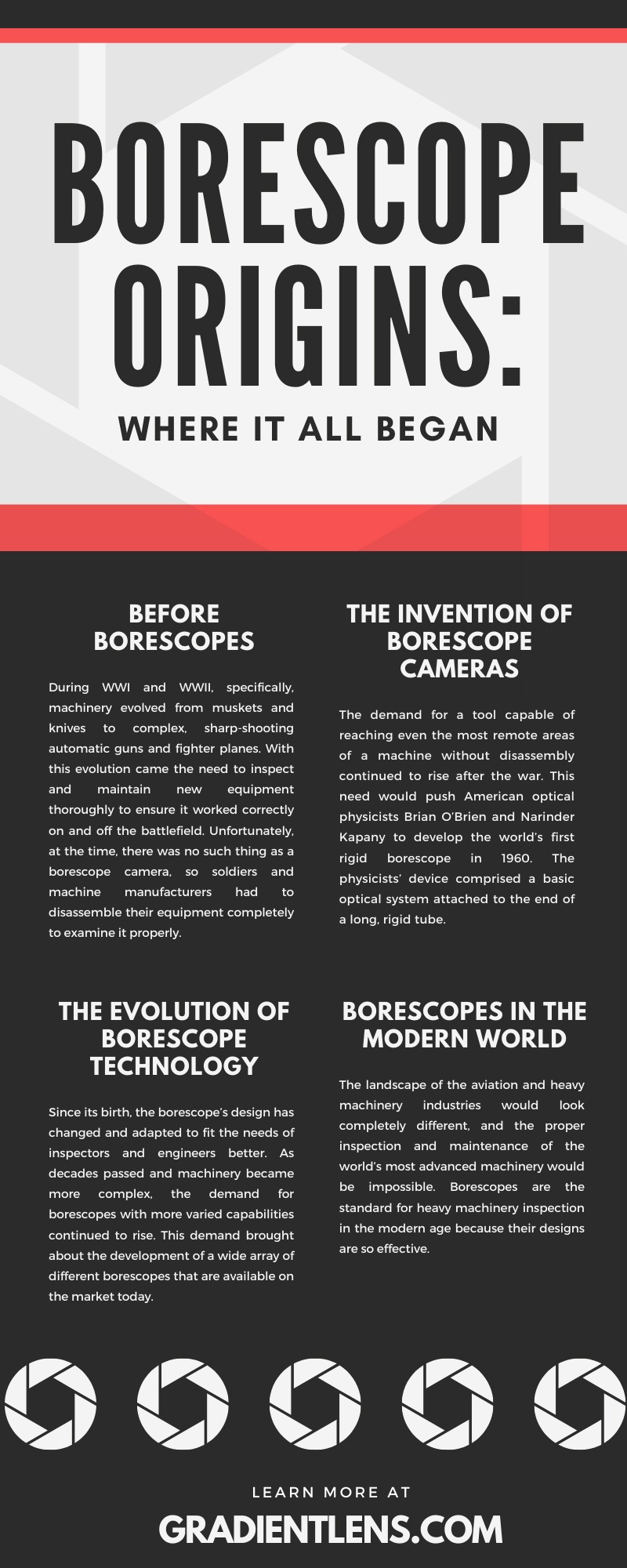

Before Borescopes

Professionals working in the turbine support systems of today have likely always had borescope cameras to assist in the inspection of remote and inaccessible areas of their machinery. However, engineers and inspectors in the early twentieth century were not so lucky. During WWI and WWII, specifically, machinery evolved from muskets and knives to complex, sharp-shooting automatic guns and fighter planes.

With this evolution came the need to inspect and maintain new equipment thoroughly to ensure it worked correctly on and off the battlefield. Unfortunately, at the time, there was no such thing as a borescope camera, so soldiers and machine manufacturers had to disassemble their equipment completely to examine it properly.

While many tried to avoid taking machinery apart by using rods crudely attached to optical systems for equipment inspections, this method rarely offered a safe and effective alternative to disassembly. As you can imagine, these alternatives not only took up an excessive amount of time but also made critical mistakes and equipment failure more commonplace. However, just twenty years after the second World War, two American physicists devised a tool that forever revolutionized the turbine support industries.

The Invention of Borescope Cameras

The demand for a tool capable of reaching even the most remote areas of a machine without disassembly continued to rise after the war. This need would push American optical physicists Brian O’Brien and Narinder Kapany to develop the world’s first rigid borescope in 1960. The physicists’ device comprised a basic optical system attached to the end of a long, rigid tube.

This invention was the first of its kind and allowed users to reach down into the smaller parts of an object and obtain clear visuals. O’Brien and Kapany’s invention forever changed the way inspectors were able to perform examinations. However, this first borescope design was still relatively limited, as it could only fit into certain kinds of tunnels due to its shape and size. These limitations inspired the need to perfect the tool’s design.

The Evolution of Borescope Technology

Since its birth, the borescope’s design has changed and adapted to fit the needs of inspectors and engineers better. As decades passed and machinery became more complex, the demand for borescopes with more varied capabilities continued to rise. This demand brought about the development of a wide array of different borescopes that are available on the market today. Three primary types of borescopes are among the most influential in their design, and they’re listed below.

Rigid Borescopes

Rigid borescopes were the very first nondestructive examination tool ever to hit the market. These devices were an enormous triumph for turbine support industries, as they allowed inspectors to investigate areas of machinery that were previously impossible to reach without disassembly. Despite their limited capabilities, rigid borescopes changed the landscape of heavy machinery by making proper inspections and maintenance safer and more thorough than ever before. These devices also laid the groundwork for the more advanced inspection tools that are now available in the modern world.

Flexible Borescopes

Developers understood that rigid borescopes were excellent tools, but they also understood the need for a product that could help inspectors reach the more flexuous and remote equipment areas. Specifically, they needed to find a way to incorporate more flexibility into the rod to keep up with the rapid advancements in heavy machinery.

Eventually, this led borescope manufacturers to devise a design for the first flexible borescope. This design was very similar to rigid borescopes, but it used an adjustable rod and fiber optic bundles to relay images, making it much more durable. Flexible borescopes also have the ability to add on attachments, such as extra light sources and adaptor kits. Additionally, this design allowed examiners access to spaces with curves and corners, making inspections and maintenance more thorough, safe, and cost-effective.

Video Borescopes

After years of tweaking and perfecting their designs, manufacturers finally landed on the beautiful, multi-featured device that we know as the video borescope. This tool is one of the most popular in the aviation, turbine support, and heavy machinery industries due to its polished design and versatility. Video borescopes share many of the same qualities as their predecessors, such as optic systems and flexibility.

However, they’re much more technologically advanced. For instance, video borescopes are capable of recording examinations in real-time, with or without illumination. These tools can also attach to LCDs that produce high-resolution images in color, and they can do so from greater distances and with more accurate measurements.

Borescopes in the Modern World

It’s clear that today’s turbine support systems wouldn’t exist without the invention of borescopes. Further, the landscape of the aviation and heavy machinery industries would look completely different, and the proper inspection and maintenance of the world’s most advanced machinery would be impossible. Borescopes are the standard for heavy machinery inspection in the modern age because their designs are so effective. Even more, these tools have helped us forge onward through every stage of machine advancement and, by extension, made our lives more convenient.

So the next time you find yourself on an international flight, cooking with fresh produce, or enjoying your favorite book under the warm glow of lamplight, think about the borescope. And remember that, without a tool capable of adequately inspecting machinery like combustion engines, automatic plows, and gas turbines, none of those luxuries would even be available to you. Hopefully, through our complete guide to borescope origins and where it all began, we’ve provided you with deep insight into why we should appreciate these unique tools.